C42200

2023-05-17 18:23:55

來源:鋼鐵之家

閱讀量:0

美國UNS

C42200

對(duì)應(yīng)標(biāo)準(zhǔn)

ASTM B591-2015

歸類

銅及銅合金

化學(xué)元素成分含量(%)

成分

Fe

P

Cu

Pb

Sn

更多

最小值

-

-

86

-

0.8

Zn余量

最大值

0.05

0.35

89

0.05

1.4

機(jī)械性能

條件/狀態(tài)

抗拉強(qiáng)度b Mpa

硬度 HBW

熱軋鋼 (M20)

275~365

1/4硬(H01),0.51≤t≤0.91 (B-Scale)

325~395

(HR)

1/4硬(H01),t>0.91 (B-Scale)

325~395

(HR)

1/4硬(H01),0.30≤t≤0.71 (Superficial 30T)

325~395

(HR)

1/4硬(H01),t>0.711 (Superficial 30T)

325~395

(HR)

1/2硬(H02),0.51≤t≤0.91 (B-Scale)

370~450

(HR)

1/2硬(H02),t>0.91 (B-Scale)

370~450

(HR)

1/2硬(H02),0.30≤t≤0.71 (Superficial 30T)

370~450

(HR)

1/2硬(H02),t>0.711 (Superficial 30T)

370~450

(HR)

3/4硬(H03),0.51≤t≤0.91 (B-Scale)

415~495

(HR)

3/4硬(H03),t>0.91 (B-Scale)

415~495

(HR)

3/4硬(H03),0.30≤t≤0.71 (Superficial 30T)

415~495

(HR)

3/4硬(H03),t>0.711 (Superficial 30T)

415~495

(HR)

硬(H04),0.51≤t≤0.91 (B-Scale)

460~545

(HR)

硬(H04),t>0.91 (B-Scale)

460~545

(HR)

硬(H04),0.30≤t≤0.71 (Superficial 30T)

460~545

(HR)

硬(H04),t>0.711 (Superficial 30T)

460~545

(HR)

超硬(H06),0.51≤t≤0.91 (B-Scale)

515~585

(HR)

超硬(H06),t>0.91 (B-Scale)

515~585

(HR)

超硬(H06),0.30≤t≤0.71 (Superficial 30T)

515~585

(HR)

超硬(H06),t>0.711 (Superficial 30T)

515~585

(HR)

彈簧(H08),0.51≤t≤0.91 (B-Scale)

565~635

(HR)

彈簧(H08),t>0.91 (B-Scale)

565~635

(HR)

彈簧(H08),0.30≤t≤0.71 (Superficial 30T)

565~635

(HR)

彈簧(H08),t>0.711 (Superficial 30T)

565~635

(HR)

Extra spring (H10),0.51≤t≤0.91 (B-Scale)

≥605

(HR)

Extra spring (H10),t>0.91 (B-Scale)

≥605

(HR)

Extra spring (H10),0.30≤t≤0.71 (Superficial 30T)

≥605

(HR)

Extra spring (H10),t>0.711 (Superficial 30T)

≥605

(HR)

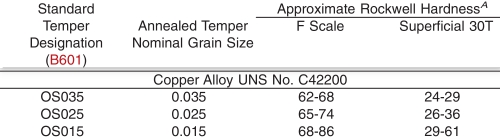

退火材料的近似洛氏硬度

Rockwell hardness values apply as follows: The F scale applies to metal 0.020 in. (0.5 mm) in thickness and over; the 30T scale applies to metal 0.015 in. (0.38 mm) in thickness and over.

注:本資料來源于互聯(lián)網(wǎng)的公開資源整理,我們不保證這些資料的準(zhǔn)確性、完整性和適用性。這些資料僅供您參考,不應(yīng)用于任何商業(yè)用途或決策依據(jù)。本資料所記載的技術(shù)信息是說明產(chǎn)品的代表性特點(diǎn)和性能的參考值,對(duì)于因誤用或不當(dāng)使用本資料所記載的信息等而造成的損害恕難承擔(dān)責(zé)任,敬請(qǐng)周知。

匯聚全球材料牌號(hào)的數(shù)據(jù)庫-鋼鐵之家

匯聚全球材料牌號(hào)的數(shù)據(jù)庫

匯聚全球材料牌號(hào)的數(shù)據(jù)庫-鋼鐵之家

匯聚全球材料牌號(hào)的數(shù)據(jù)庫